LASER CUTTING

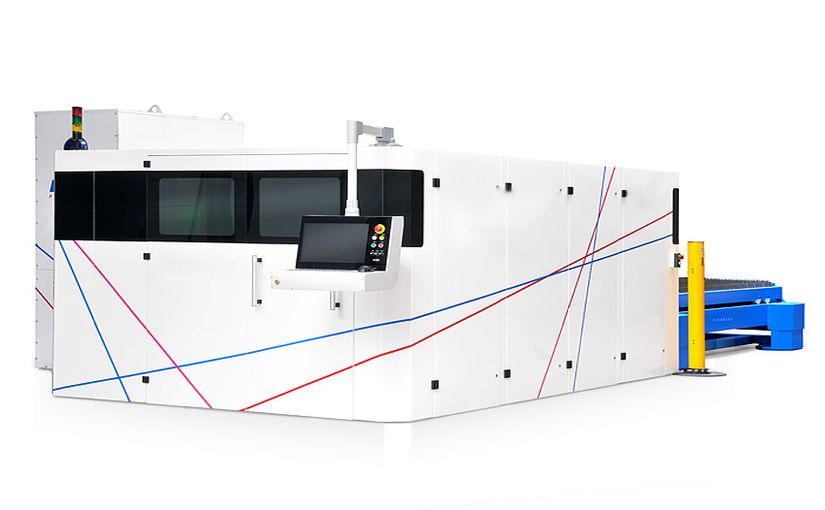

Sheet metal laser cutting is our company's specialty. . It is made with high accuracy on a modern fiber laser. This guarantees high repeatability and precision of laser-cut details. Check out our modern machine park and laser cutting in the city of Częstochowa.

- Max. dimension of the element to be cut: 2000 x 4000 mm

- Max. black sheet thickness: 15 mm

- Max. stainless steel thickness: 8 mm

- Max. aluminum sheet thickness: 8 mm

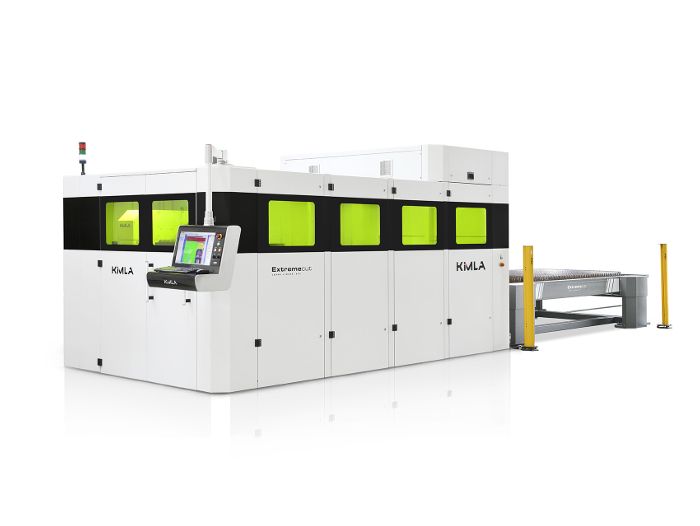

New 6kW laser

- Max. dimension of the element to be cut: 1500 x 3000 mm

- Max. black sheet thickness: up to 25 mm

- Max. stainless steel thickness: up to 15 mm

- Max. aluminum sheet thickness: up to 15 mm

ADVANTAGES OF LASER CUTTING:

- High cutting precision, high accuracy enables the execution of an element that does not require further finishing

- 100% repeatability of shapes

- High speed of the cutting process and concentration of energy ensure a narrow heat-affected zone, and thus less deformation of the detail

- Material savings due to the narrow cutting gap

- Smooth and clean cut surface: no additional finishing necessary

- High flexibility of the laser cutting process. (possibility to cut both one element and several thousand)

- Any shapes of elements cut by lasers.

ASK FOR A QUOTE

Write us a message and ask for a quote for the services that interest you.

Laser cutting is the most convenient and, at the same time, the most precise method of material processing. The surfaces cut in this way are perfectly even and smooth, and also clean, so they do not require additional processing. Our company Lepsod specializes in laser cutting of various materials , mainly aluminum and stainless steel. We perform these works with the use of a modern laser, which guarantees high repeatability and precision of the details cut by the laser.

Laser cutting services in Częstochowa - advantages

The undoubted advantages of such laser cutting are:

• excellent cutting precision - thanks to the remarkable accuracy, the cut surface is smooth and clean, so there is no need for further finishing;

• one hundred percent repeatability of shapes;

• material savings due to the narrow cutting gap;

• high cutting speed as well as the concentration of energy result in a narrow heat-affected zone, which reduces the deformation of the detail;

• thanks to the high flexibility of laser cutting, it is possible to cut one piece or even several thousand pieces;

• freedom in cutting any shapes on selected elements of the material.

Laser cutting in Częstochowa

There is no more precise method of cutting decorative elements in various materials than laser cutting . Using this unique method, it is possible to shape thinner products such as aluminum sheets and construction materials such as stainless steel. This is what our company Lepsod, located in Częstochowa, specializes in.

We offer our clients various types of interior decorations, for example in the form of decorative hangers, clocks, inscriptions with a selected message or even walls and tables. Of course, the possibilities in this matter are endless, because we also realize individual orders. So the only limitation here can be your imagination.

Among our proposals, a significant place is occupied by modern, and at the same time functional panel fences. They can take the form of spans, balustrades, gates or wickets. The undoubted advantage of such a solution is the possibility of personalizing the pattern on such a panel, as well as its easy assembly. It is worth mentioning that the steel processed on the latest laser devices achieves the highest quality, and therefore will certainly meet the expectations of even the most demanding customers.

Laser cutting Częstochowa - the highest quality of services

Our company employs only specialized employees who have extensive experience in making laser cuts in metal materials, which is why we undertake any, even the most difficult challenges, placed on a special order. Our clients can count on professional technical advice on the selection of the optimal solution, as well as on a quick quote.

Thanks to the innovative laser technology, it is possible to use the sheet surface to the maximum and make cuts of both small and large metal elements of any shape.